SentryGlas SGP Laminated Glass

Complete Guide to SGP Laminated Glass

SentryGlas® Interlayer for Superior Safety

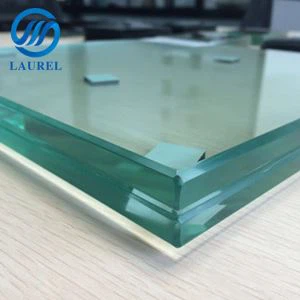

SGP laminated glass is a type of safety glass that uses SGP (SentryGlas® Plus) ionoplast interlayer between two or more glass panels. Originally developed by Dupont and now produced by Kuraray, the SentryGlas interlayer offers far greater performance than traditional PVB (polyvinyl butyral) interlayers.

Compared with standard laminated glass, SGP glass provides higher strength, better weather resistance, superior clarity, and long-lasting edge stability, making it the preferred choice for architectural projects requiring the highest safety and transparency.

Common names: SGP laminated glass, Sentry laminated glass, SentryGlas Plus interlayer, Kuraray SentryGlas, Dupont SGP interlayer.

History and Manufacturing

HISTORY OF SGP

The SentryGlas Plus interlayer (SGP film) was first created by Dupont SGP under the name Dupont SentryGlas Plus.

Today, it is produced and marketed by Kuraray SentryGlas, becoming the world standard for high-performance laminated glass.

MANUFACTURING PROCESS

Pre-treatment – glass cleaning, polishing, and edge processing.

Assembly – SGP film placed between two or more glass sheets.

Roll pressing & vacuuming – removing air to ensure bonding.

Autoclave process – high temperature and pressure fuse glass and film into a single structure.

The result is SGP glass lamination with outstanding strength, clarity, and long-term durability.

|

|

ADVANTAGES OF SGP INTERLAYER

Superior strength

Twice the load-bearing capacity of PVB laminated glass, with only one-quarter the deflection.

Impact & blast resistance

Withstands hurricanes, explosions, and forced entry better than traditional laminated glass.

Excellent edge stability

Resistant to moisture, delamination, and yellowing. Yellowing index ≤1.5 (vs. 6–12 for PVB).

High clarity

The SentryGlas interlayer maintains transparency over time, especially when paired with low-iron glass.

Tear resistance

5 times stronger than PVB, able to act as a structural element. Even after breakage, glass remains safely bonded.

UV protection

Strong resistance to UV radiation without discoloration.

|

|

|

|

|

|

|

|

|

|

SGP vs PVB: How to Choose the Right Interlayer?

|

Property |

PVB Laminated Glass |

SGP Laminated Glass (SentryGlas®) |

|---|---|---|

|

Strength |

Standard |

2x stronger, 1/4 deflection |

|

Tear resistance |

Moderate |

5x stronger |

|

Edge stability |

Susceptible to moisture, bubbles, yellowing |

Excellent water & weather resistance |

|

Transparency |

Yellowing index 6–12 |

Yellowing index ≤1.5, ultra-clear |

|

Applications |

Standard safety glass |

High-end façade, hurricane-resistant, glass bridges, railings |

|

|

|

|

|

|

Selection Tip:

For standard interior glazing → PVB laminated glass is sufficient.

Cost-sensitive projects where optical clarity degradation is acceptable

For outdoor façades, structural glass, hurricane zones, glass bridges, and high-security projects → SGP laminated glass is the best choice.

Edge Finishing & Processing Options

SGP glass interlayer supports various finishing and deep processing:

Edge processing – polished or beveled to protect the SGP interlayer.

Machining – drilling holes, notching, cut-outs, and shaping.

Safety processing – tempering, heat strengthening, or curved glass lamination.

Combination options – compatible with silk-screen printing, acid etching, fire-resistant layers, bulletproof lamination, or decorative finishes.

Even after extensive processing, the SentryGlas Plus interlayer maintains strong adhesion and long-lasting performance.

|

|

Applications of SGP Laminated Glass

Curtain walls & point-supported façades

Glass bridges & glass walkways

Balustrades & glass railings

Observation decks, skylights & airport canopies

Hurricane-resistant & blast-resistant glazing

High-end showcases and interior decoration

Thanks to its unmatched safety and clarity, Sentry laminated glass is widely used in landmark architecture and premium projects worldwide.

Why Choose Laurel Glass as Your First Choice?

When selecting laminated glass, quality, skill, and professionalism matter.

Laurel SGP Laminated Glass uses Kuraray SentryGlas® or Dupont SentryGlas Plus interlayers, ensuring top performance in safety, strength, and transparency.

Maximum safety – Even when broken, glass remains bonded without falling apart.

Durability – Resistant to moisture, UV, and outdoor aging.

Structural performance – Functions as part of the load-bearing system, reducing framing costs.

Optical quality – Superior clarity for architectural aesthetics.

Long-term value – While SGP glass price / SentryGlas price is higher than PVB, the extended lifespan and reduced maintenance deliver greater overall savings.

Our advantages:

Advanced technology – vacuum lamination, autoclave processing for precision.

Skilled craftsmanship – experienced professionals with global project expertise.

Premium materials – original Kuraray SentryGlas® interlayers and Dupont SGP film.

Tailored solutions – custom SGP glass thickness, sizes, and finishes for any project.

Whether for skyscraper façades, glass bridges, or high-security glazing, Laurel Glass delivers SGP laminated glass solutions that meet international standards in strength, clarity, and durability.

SGP laminated glass (SentryGlas®) stands as the ultimate safety glass for modern architecture, combining superior mechanical performance, edge stability, clarity, and UV resistance.

For projects that demand excellence, Laurel Glass provides reliable solutions with SentryGlas Kuraray and Dupont SGP interlayers, ensuring beauty and safety for decades.

Hot Tags: sentryglas sgp laminated glass, China, suppliers, manufacturers, factory, customized, wholesale, buy, price, bulk, in stock, free sample

You Might Also Like

Send Inquiry